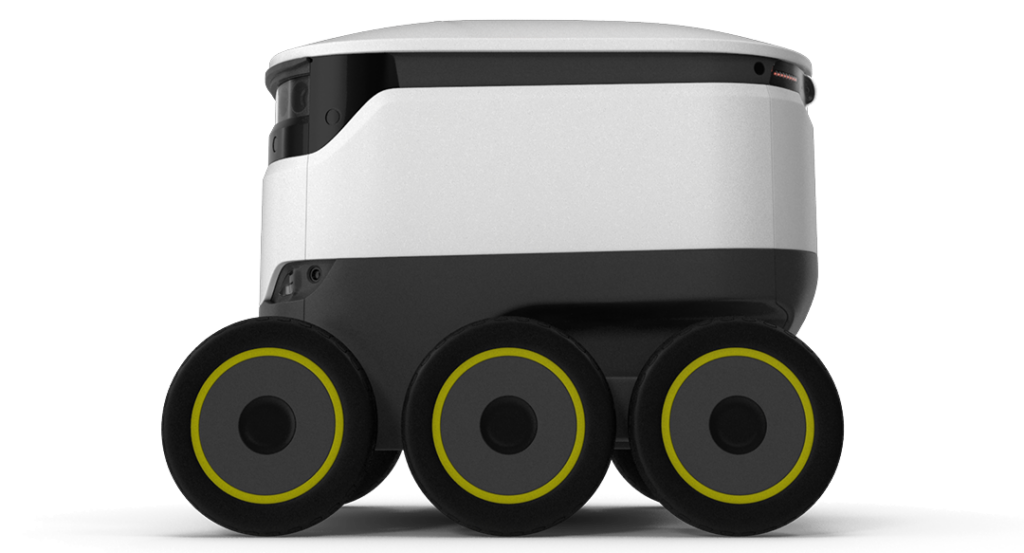

ACR systems are highly efficient Goods-to-Person solutions designed for totes & cartons transportation and process optimization, providing efficient, intelligent, flexible, and cost- effective warehouse automation solutions through robotics technology.

Greatly increase warehouse storage density, High space utilization rate.

Greatly increases workforce operational efficiency.

Responds quickly to business needs, achieving fast deployment.

HAI ROBOTICS invented and continues to pioneer Autonomous Case-handling Robot (ACR) systems in 2015. The first ACR system, HAIPICK system, completed development and testing in 2016, officially launched in 2017, and was put into commercial use in 2018.

The combination of HAIPICK ACR and HAIQ software platform flexibly meets the needs of

various production lines. It enables access to the raw material area, buffer area, finished and

semi-finished product storage areas, and production lines, realizing information

management and creating a fully automated intelligent manufacturing logistics solution.

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.