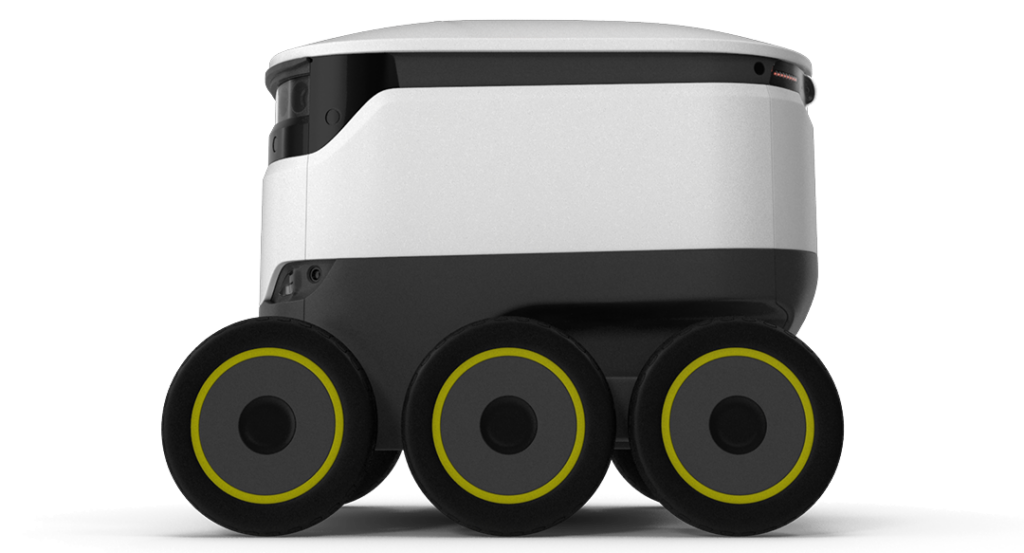

Automated material handling solutions shorten the daily distance regularly covered by a warehouse worker, taking a large physical burden off the human workforce. Material handling robots, which can be implemented in a relatively short time, can increase handling efficiency and accuracy by at least 50% in all warehouses and logistics centres – shortening lead times and improving work efficiency.

No need to change the environment: the robots navigate autonomously through the warehouse with advanced QR code and LIDAR sensor navigation, move safely with automatic obstacle avoidance - and can work with the human workforce. They are ideally suited for situations requiring complex human-robot interaction.

Automated material handling systems can help minimising accidents in the warehouse and reduce the physical strain on the worker, thus increasing work safety. Human workers working alongside robots do not have to work in dangerous areas (high shelves) or with heavy loads (goods with large size and/or weight). This improves occupational health and well-being of workers and reduces the risk of injuries.

With automated warehouse management systems linked to robotic solutions, the status, movement and routing of stored products can be tracked in real time. In addition, continuously updated stock information improves inventory management and helps to manage goods more accurately, improve data-driven decision-making and provide information for more optimal warehouse layout – for example, data can be used to move more frequently moved goods to more accessible locations.

Material handling robots can move stock around the warehouse faster and more efficiently. With increased speed and the ability to operate continuously, tasks are completed faster and take less time than with human labour. Robots are highly accurate and reliable. This reduces the possibility of errors and mistakes, which can have a significant impact on warehouse operations, product tracking and end-user satisfaction.

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.