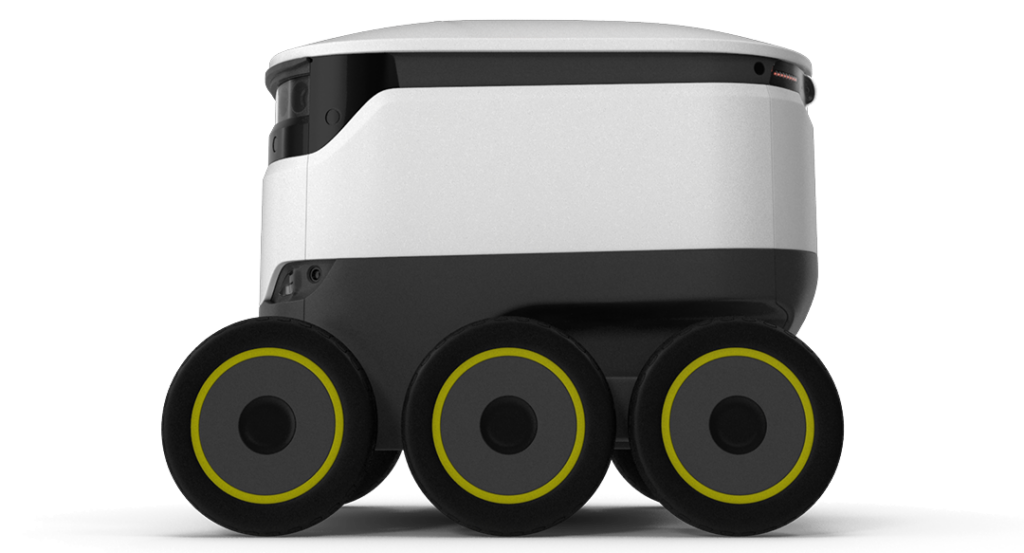

Agilox is a leading manufacturer of autonomous mobile robots used in the logistics and manufacturing industries to automate internal logistics processes. Their passion is to revolutionize intralogistics. AMRs improve efficiency and productivity, reduce labor costs, and provide users with great flexibility. The company stands for the revolutionary further development of theese automaterd comission robots. Material-handling robots automatically detect obstacles and workers and react safely and autonomously to the given situation. They can be widely used in the fields of logistics and production, and offer extremely great advantages to users.

Their work enables customers to flexibly design their intralogistics with the help of their products. To achieve this, they have developed the most maneuverable pallet AMR for the industry. Agilox vehicles’ find their way in any area. The omnidirectional drive concept ensures that there is enough space, even in the smallest aisle. They also have solution for dynamicall material flow changes.

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.