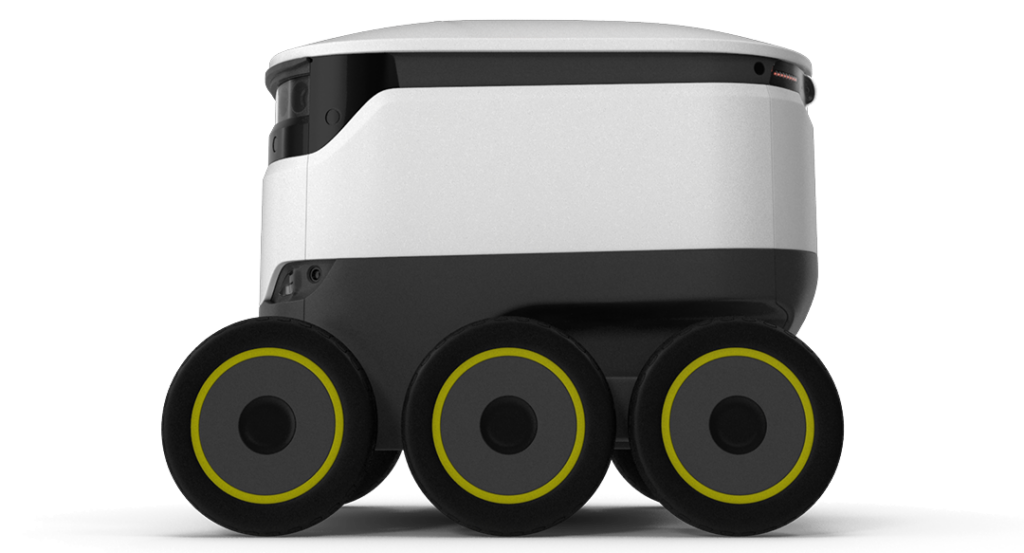

The current automotive manufacturing line is not flexible enough to adapt to rapid market changes. The traditional material handling system is labor-intensive with potential risks of mixed man-machine operation.

Advanced Robotics provides professional supply chain consulting and robot solutions to build an intelligent and flexible manufacturing and logistics system for automobile and auto-parts businesses.

Geek+ Smart Picking system is used in factory storage, manufacturing supermarket, and VMI to ensure accurate and transparent inventory data

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.