Exotec’s picking solution provides outstanding performance on the market, is flexible and fully adaptable to the customer’s needs. The sizing of the system takes into account the available space and storage requirements. This makes it extremely adaptable to the specifications of the warehouse and the logistics center, and at the same time, future expansion can be planned more easily. The racks adapt to the design of the warehouse, so the system is able to make maximum use of the area. Sizing is based on floor area and interior height. With robots moving vertically on racks that can be built up to a height of 12 m, the storage space can be used to the maximum in three dimensions, and the density can thus be up to five times that of traditional rack picking.

Skypod can adapt to changes in expectations. In warehouses, the need to increase capacity increases during peak periods, With Exotec’s solution, it is enough to expand the system with new robots. The bots function as a fleet, helping workers prepare orders faster. The robots are constantly given tasks and instructions, which they can prioritize based on their programming.

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

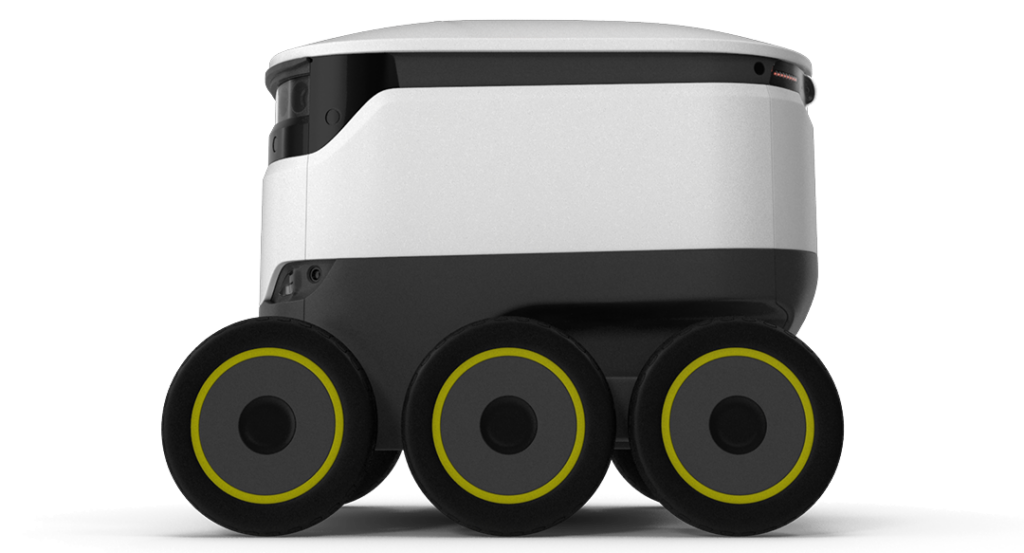

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.