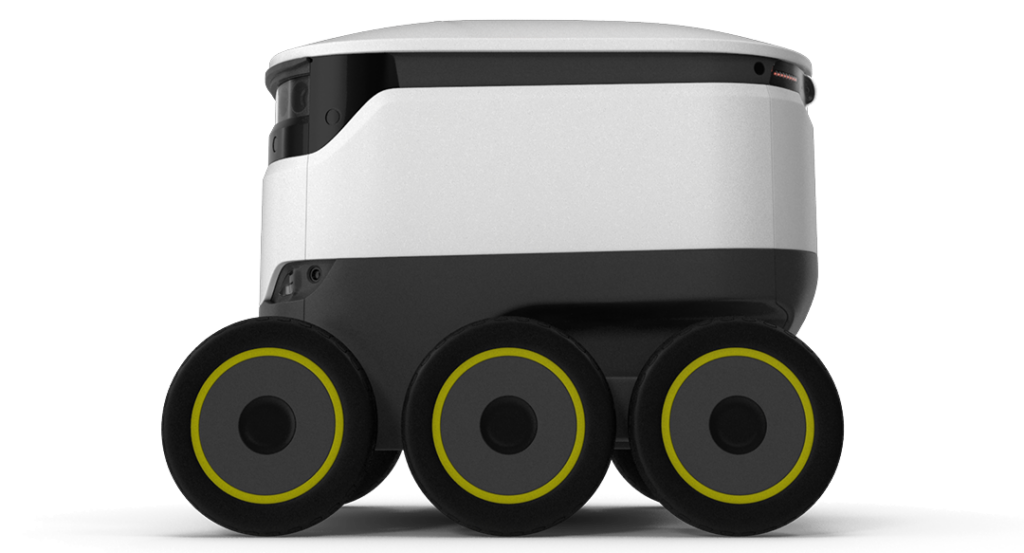

Agilox is a leading manufacturer of autonomous mobile robots used in the logistics and manufacturing industries to automate internal logistics processes. Their passion is to revolutionize intralogistics. AMRs improve efficiency and productivity, reduce labor costs, and provide users with great flexibility. The company stands for the revolutionary further development of theese automaterd comission robots. Material-handling robots automatically detect obstacles and workers and react safely and autonomously to the given situation. They can be widely used in the fields of logistics and production, and offer extremely great advantages to users.

Their work enables customers to flexibly design their intralogistics with the help of their products. To achieve this, they have developed the most maneuverable pallet AMR for the industry. Agilox vehicles’ find their way in any area. The omnidirectional drive concept ensures that there is enough space, even in the smallest aisle. They also have solution for dynamicall material flow changes.

Agilox autonomous mobile robots (AMRs) revolutionize intralogistics, enabling efficient and flexible material handling. These intelligent systems optimize warehouse processes, reducing costs and increasing productivity. Discover how the introduction of Agilox robots can help your business!

Agilox robots are able to move autonomously in the warehouse, and thanks to their intelligent navigation systems, they perform tasks accurately and quickly. AMRs minimize waiting time and eliminate unnecessary manual material handling.

Agilox’s system can be easily integrated into the existing warehouse infrastructure. Thanks to their scalability, they can be used in warehouses of any size, whether it is a small business or a large logistics center.

The introduction of Agilox AMRs results in significant cost savings in the long term. Automation reduces the need for labor and also minimizes the costs resulting from errors, thereby increasing the company's profitability.

AMRs are equipped with advanced personal protection sensors to ensure safe operation. They are able to detect and avoid obstacles and cooperate with human workers, thus increasing the safety of the work environment.

Agilox systems can be easily integrated with existing warehouse management systems (WMS, ERP). Our company provides full support after installation, including maintenance services and staff training to ensure smooth operation.

The introduction of AMRs not only increases efficiency, but also contributes to sustainability. Energy-efficient operation and accurate material handling reduce the ecological footprint of the warehouse. AMRs provide a quick return, so the investment will bring you a profit in a short period of time.

Agilox robots are manufactured in accordance with the strictest safety standards, ensuring safe operation and the protection of warehouse workers. Their advanced sensor systems and algorithms guarantee automatic navigation in any warehouse environment, with advanced obstacle avoidance, so that the current layout and shelving do not have to be changed during installation.

They have an advanced AI-based navigation system that enables autonomous movement and dynamic route planning. They continuously collect and analyze data from their environment, thereby optimizing warehouse processes.

The introduction of Agilox’s solution not only increases warehouse efficiency, but also contributes to gaining a competitive advantage. Automated systems allow your business to respond quickly and flexibly to market changes, increasing profits and customer satisfaction.

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.